October 15, 2021

Formshrink®: 80% packaging weight reduction + significantly increased shelf-life compared with a conventional packaging format.

Discover how Formshrink® can increase your production output whilst reducing operation costs.

January 12, 2021

PVDC (Polyvinylidene Chloride) has been used as a barrier in fresh meat packaging for decades, but increasing environmental concerns are urging packaging producers and retailers around the world to revisit its use and develop viable alternatives.

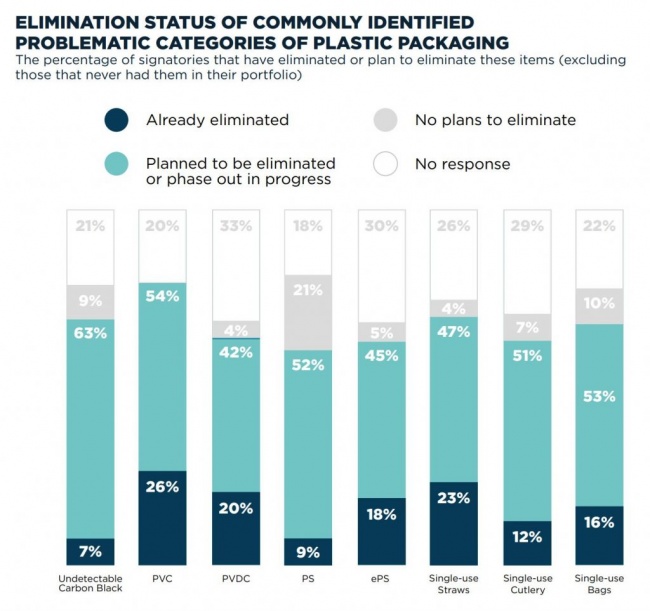

In 2018, the Ellen MacArthur’s Global Commitment initiative reported that 62% of brands, retailers and packaging producers in their signatory group (400+ organisations worldwide) have already eliminated or are planning to phase out PVDC materials from their portfolio by 2025.

In the UK, leading retailer Tesco announced strict ban on PVDC materials by the end of 2019. The latest Progress report by UK Plastics Pact also shows that the elimination of PVC/PVDC is part of the sustainability objectives of most UK retailers by 2025.

There are several reasons why PVDC barrier structures are considered harmful to the environment

1. PVDC packaging is not currently recyclable.

This is true both for mechanical and chemical recycling systems.

2. Obstacles for mechanical recycling of PVDC

3. Obstacles for chemical (feedstock) recycling of PVDC:

At present, chemical recycling for PVC/PVDC packaging does not exist at scale.

4. Currently the only after-use options for PVDC are either landfill or incineration.

Neither of these after-use pathways is considered environmentally friendly due to the release of toxic chemicals. When incinerated, PVDC generates considerable quantity of dioxins – a well-known potent human carcinogen. The hydrogen chloride gas evolving from PVDC’s incineration also discourages its use in the industry.

PVDC provides excellent barrier to both oxygen and water vapour. Most alternative barrier polymers offer just one or the other.

Fresh meat is packed in wet and humid environments. It is therefore paramount for meat packaging to maintain its barrier properties when exposed to high-moisture environments.

Since PVDC’s permeability properties are unaffected by relative humidity, it can deliver consistent protection for dry and high-moisture environments allowing shelf life of fresh meats of up to 100 days.

EVOH (Ethylene vinyl alcohol) is a non-chlorine barrier alternative for fresh meat packaging and is readily available today. However, EVOH has been thought to be sensitive to high moisture packing conditions, especially at a relative humidity of above 80%. This common perception has limited the wider use of the material so far.

Recent innovations in extrusion technologies, however, provided opportunities for the increased use of EVOH through engineering EVOH-based multilayer barrier structures that offer shelf life maintenance for fresh meats unaffected by high humidity.

A recent study compared such highly engineered EVOH-barrier shrink bags with traditional PVDC-based bags and indicated that both packaging solutions achieved similar meat quality levels under controlled storage.

EVOH is also considered recyclable – it can be tolerated by mechanical recycling streams within certain percentages and can be handled by chemical recycling.

The barrier needs will of course heavily depend on the type of application. However, we can roughly divide the fresh meat barrier packaging market into two main segments based on shelf life requirements:

We can therefore argue that PVDC shrink bags are not actually necessary at retail level or for European primal shrink bag formats as there is no real need for shelf life extension beyond 70 days.

Even export meat requirements can be met with EVOH-based (non-chlorine) structures with evidence of meat packers actively achieving over 90 days shelf life for export beef, with some case study examples of 130 days.

As explained above, the resistance to phase out PVDC has mainly been driven by the perception that no alternative can meet the barrier requirements of fresh meat applications at high relative humidity.

This argument, however, has been ruled out by extensive research and trials over the past years, proving that EVOH is a viable solution. At present, EVOH-based shrink barrier bags account for approximately 15% of the shrink barrier bag market.

A potential barrier to change, however, remains the high cost and investment required by packaging suppliers to replace their PVDC-based extrusion technology with one suitable for EVOH-based structures.

Last but not least comes the point of cost neutrality. Existing PVDC-based recipes use cross-linking technology, allowing lower cost resins to be used. EVOH resins have a higher price per kilo than PVDC & Polyolefin (PO) resins.

However, specially engineered EVOH structures can be extruded “thinner but stronger”, meaning less plastic used. For instance, Krehalon’s patented non-chlorine ML40 technology is over 20% thinner than conventional shrink bags.

Krehalon have been the leading producer of EVOH-barrier shrink bags for over 40 years. We have a wide array of application knowledge and experience in the development of high barrier non-chlorine grades for fresh meat applications.

We are happy to offer evidence-based advice and expertise should you wish to further improve the sustainability of your fresh meat packaging. Contact us today via our website enquiry form or get in touch with your local sales representative.