We all strive to protect our climate and we are making great efforts to develop packaging that is as environmentally friendly as possible. Naturally, there are different approaches that are usually very difficult to compare. This means it is difficult to say exactly which packaging is really more environmentally friendly than another. If you take a step back and think about what the purpose of the packaging is, then it is very clear: to provide the best possible protection for a product. Some new packaging, which at first glance appears to be particularly environmentally friendly, offers significantly less product protection.

“Food waste” is a term we often hear, and there are incredible figures of how much food ends up in the rubbish. The causes are of course many and varied. If packaging is extremely environmentally friendly, but offers less product protection, the food spoils more quickly and can end up in the wastebin. Have we then done something good for the environment because of the environmentally friendly packaging, or have we done more harm because the product is ultimately spoiled?

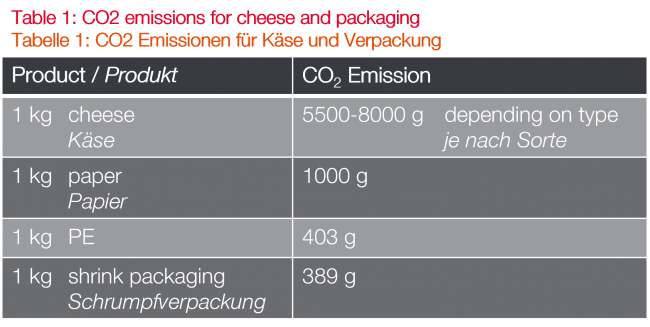

A very good method to measure how little or how bad the product and/or the packaging is for the environment, is to look at the CO² emissions of the entire life cycle. Here, of course, a closer look is taken not only at the packaging, but also at the product, in relation to food waste. For this, average values are shown below in Table 1.

The packaging should protect the product as much as possible while, at the same time, allowing maximum shelf life thereby minimising food waste, and of course all while fulfilling the design requirements. Various parameters are important surrounding the question of shelf life. These depend on the type of cheese and surface texture, the oxygen permeability and/or barrier, as well as the puncture resistance parameters for the stability of the packaging.

Packing sliced cheese

Most standard sliced cheese packaging (for 200 - 250g cheese weight) weighs approximately 12g. These are designed as MAP* (modified atmosphere) packaging, which is important otherwise the cheese slices would stick together.

If the same cheese slices are packed in shrink packaging like Formshrink®, also as a MAP pack, then the packaging has a weight of 2g. This corresponds to a saving of more than 80% material. The photo below shows cheese slices wrapped in 2g Formshrink®.

An easy-tear tab can be incorporated into the packaging so that it is user-friendly and easy to use. The Formshrink® packaging has a significantly higher puncture resistance than the standard packaging, even if one would not suspect this due to the appearance. This means Formshrink® offers an attractive combination offering maximum product protection with a minimal use of materials. Furthermore, Krehalon is able to print designs using up to 10 colours, making almost any design possible.

Packing cheese blocks

When packing a 400g piece of Emmental, the packaging typically weighs 4g on average; when packed in Formshrink®, the packaging has a weight of just 2g. This is a clear material savings potential of 50%, see photo below of 400g Emmental cheese wrapped in Formshrink®.

If you look at the range of cheese slices sold in stores, it quickly becomes apparent that the plastic savings potential is enormous. This, at the same time as offering higher product protection and the associated possibility of longer shelf lives.

Of course, the thought must be extended to what happens to the packaging when it is no longer needed? Recycling is the buzzword where the opinion can quickly form that recyclability solves all problems. This is exactly where the problem lies, it is an opinion, not a fact. Put simply, with recyclability, you cannot just rate the environmental friendliness of packaging as good or bad; the situation is much more complex and requires a closer look. If you look at various studies on this, all reflect the client's desired result and are extremely different, so a closer look is unsuccessful. I am not aware of absolutely neutral numbers at the moment. Any recycling is good, but it also generates CO2 emissions that must not be ignored.

The approach in the first instance, is to save as much material as possible, and thus shrink packaging like Formshrink® offers the opportunity to produce much less packaging waste that then has to be recycled.

Price also plays a role. Plastics were extremely cheap until a year ago. Since then, plastic prices have been rising steadily, and there is no end in sight. In addition to environmental considerations, this is also a purely economic aspect to save as much material as possible without having to compromise on product protection.

The second step is to recycle, and this is also complicated. With standard recycling, the legislator does not allow plastic from the standard recycling process to come into contact with food. This means that the recycled plastic has to be embedded into an extra layer within the packaging, which increases complexity, effort and also CO2 emissions. With chemical recycling, it is possible to use it to produce plastics that are allowed to come into contact with food. This process is well-established in Germany and there is some packaging on the market that is made from a high proportion of chemically recycled plastics. There are many developments in this area at the moment; the future remains exciting.

In the sense of our responsibility to protect our planet on behalf of our children, all packaging arguments have to be checked repeatedly. Consuming significantly less material with the same or better properties as the current standard is a good start.

* MAP = modified atmosphere packaging – a way to extend product shelf life by substituting the atmospheric air inside the pack with a protective gas mix.

Werner Rist, Cheese Specialist at Krehalon

[Translated from the German technical article published in November 2021 edition of Molkerei Industry].