With modern methods of ripening and packaging, the seasonal differences between milk and sales quantities can be better controlled. The cheese production and subsequent maturation can be slowed down or even accelerated. At the same time, a significant reduction in the maturation process is possible.

A major challenge for the manufacturers of spicy, smeared cheeses (cheese with surface ripening) is the question of when and how much cheese should be produced. Cheese with surface ripening has to be treated with a mixture of water, salt and bacteria during the ripening period, this requires a lot of time and effort.

An additional difficulty is the amount of milk produced; the fluctuations in the delivery and production rarely match. New processes for maturation and packaging offer a solution here.

One possibility is to shorten the maturation for smeared spicy cheese. The evaluation of this possibility was carried out by KLEVERTEC (competence centre for applied research in food and packaging technology) in Kempten.

At the beginning of the process, everything stays the same; the cheese is produced and treated after the salt bath. From here the change begins. After a certain period of maturation, the cheese is packed into shrink bags. It is extremely important in this process step that no vacuum is created – the bags are packed “with air”. This is very important so the micro-organisms for the surface ripening are not damaged. During the subsequent shrinking process, a slight overpressure is generated in the bag. The bags with cheese are then further ripened at the same temperature as in the ripening room (see illustration below).

ILLUSTRATION: Cheese wheels with oxygen and pressure sensors. Source: Fraunhofer IVV, KLEVERTEC AHa Bericht_KT_10012_19_Krehalon_de

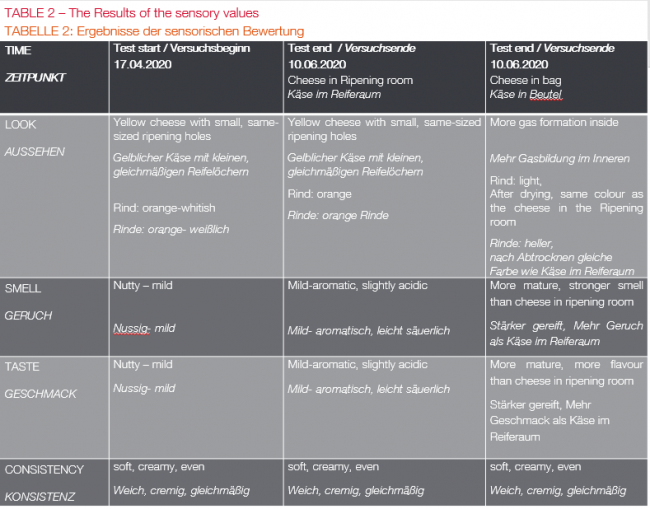

Further treatment is not necessary. After a predetermined time in the maturation bag, the cheese is unpacked again and left to dry for 1-2 days as the moisture in the bag is evenly distributed and the cheese is wet when it is unpacked. After the drying time, the cheese can be used without any further treatment. The cheese matured with shrink packaging has lost significantly less weight and has a more intensive flavour (tables 1 + 2).

Evaluation of the Results

In its report, the KLEVERTEC Institute comes to the following assessment of this method:

To evaluate the results, it can be said that the cheese wheels in the bags that were stored at the Klevertec were more mature. This was checked with a sensory analysis at the beginning of the experiment (all cheese wheels unpacked) and at the end of the experiment. The weight loss for the cheese wheels in bags was significantly less than for the cheese wheels without packaging in the ripening room (approx. 12% in comparison), which is probably due to the packaging. The packaging creates a water vapour barrier around the cheese, which greatly restricts drying or water loss.

SOURCE: Fraunhofer IVV, KLEVERTEC AHa Bericht_KT_10012_19_Krehalon_de

Endless Possibilities

As is generally the case with cheese maturation, the possibilities here are almost endless. Over the maturation time with smearing, the period of time the cheese stays in the bag, and the temperature and/or culture changes (e.g. other strains, more/less cultures), an almost infinite number of different types of cheese can be produced with significantly reduced maturation time, and yet have a very intensive taste.

Close cooperation between the dairy and the packaging manufacturer is essential. The production/ripening of cheese are mostly separate worlds. For the success of these methods, it is imperative that the packaging manufacturer has a precise knowledge of what is being packed, since the temperature and timings are important for success. In this way, packaging and product development are connected to each other.

Another possibility of milk quantity and production control is a delayed surface ripening with water, salt and bacteria (smearing). Also in this case, the cheese production begins in the same way; the difference begins after the salt bath. After the cheese has dried, it is packed in a high-barrier shrink bag (this is for cheese with little or no gas production) and can be so-stored either at the usual temperature, or at a lower temperature to extend the ripening time in case the cheese is only needed later. This is also the reason for the high barrier; cheese packed in this way can be stored for up to one year. At the same time, shrink packaging uses the minimal amount of material with the maximum product protection. In the case of semi-hard and hard cheese, the shrink packaging also helps to shape the cheese. Between 2-4 weeks before the cheese is required, depending on the desired taste intensity, the cheese is unpacked and treated as normal in the ripening room.

In this way, cheese can be produced when the milk is available, and the maturation is adjusted to the period when the cheese is needed. This is used, for example, in tourist regions, when cheese is produced throughout the year, and the annual amount is sold during the summer months. At the same time, this procedure also enables a significant reduction in the maturation time.

These methods increase the flexibility in the planning of dairies for Production and Sales at the same time as facilitating a significant reduction in the maturation process.

Werner Rist, Cheese Specialist at Krehalon

[This technical article was published in German on 23 August 2021, in the Deutsche Molkereizeitung].