Staff shortages are the latest challenge to hit the meat industry, which is resulting in either carcasses being exported to be butchered before returning to UK to be sold, or worse still, healthy livestock being culled.

Over the past 40 years, the shrink bag market has been a manual and labour-intensive process of packing fresh meat. Labour costs have always been significant in any food factory, and now there is no labour! However, there is a tried and tested solution available in the form of automation. For over a decade, Krehalon has been offering automated packing solutions.

The most obvious benefit in the light of the current labour short fall is less operatives are required in the process and the correlated reduction in labour costs. Even if an initial investment needs to be made to acquire equipment, this is soon alleviated by the increased production efficiencies and in the mid-long term, the financial savings become more attractive.

Besides the labour advantages, there are also other benefits that address the growing pressure to reduce a product’s carbon footprint and to have sustainable packaging. As a manufacturer and distributor of shrink barrier packaging solutions to the fresh food industry, our primary focus at Krehalon, is to help customers maximise product shelf life (i.e. reduce food wastage) and visual product appeal. Integral to that, we focus on sustainable operational efficiencies and long-term commercial gains for customers.

SBR™ solutions can provide a higher production output, due in part because:

- Less pack leakers due to clean, hermetically sealed packs

- Material usage savings – due to efficient product material sizing to compliment the automated equipment, maximising the number of packed products per m2 of film.

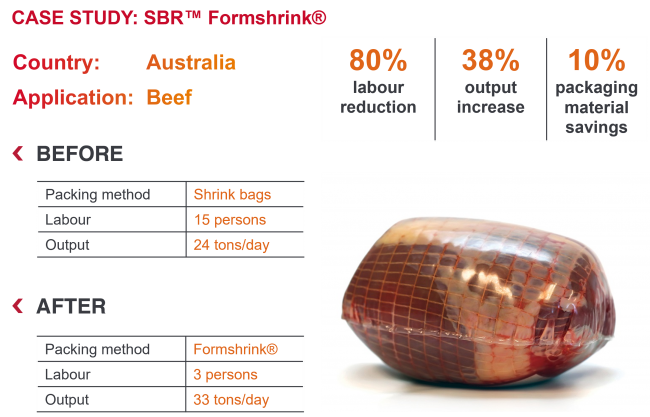

The case study below illustrates the savings made with Formshrink®, our thermoforming technology using two separate shrink films. This is ideal for consistent and uniform shape, high volume products.

We also understand that our SBR™ solutions can be thinner than alternative options on the market.

Reduced labour + Less plastic + Less waste

Contact our UK Sales team today to discuss how our solutions may help you.